Friday, February 2, 2024

Journey from the source: Green Line materials from TROTEC

2024Visual CommunicationDigital printing

Learn how the laser engraving solutions specialist prepares one of the materials in its range that is most committed to sustainability: TroWood Solid.

For some, recyclability is paramount, while for others, it's the raw material composition that matters. Aware that sustainability can be reflected in different ways across products, Trotec, an exhibitor at C!Print Madrid , designed its Green Line of materials.

For Trotec, sustainability is not a destination, but a continuous journey of improvement and responsibility. The company continually strives to expand its range of sustainable laser materials, pushing the boundaries of eco-innovation and inspiring others to join it on this journey. In this article, you'll learn about the materials selection process.

Sustainable sources

The wood for TroWood Solid panels is sourced in Europe from forests that are home to native trees. Trotec's partners' commitment to sustainable forest management goes beyond mere certifications; they actively participate in regular inspections and adhere to ethical sourcing practices. This dedication ensures that the wood they source meets the strictest sustainability standards .

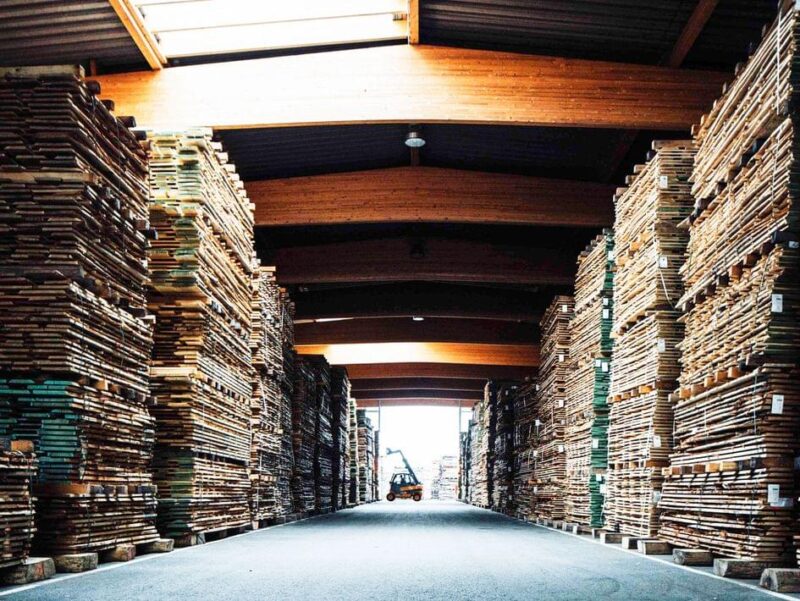

Furthermore, panel production is of the highest quality. The process begins with the careful selection of the wood, which is then cut into planks and stored in optimal conditions for up to two years. This precise storage period facilitates the gradual release of moisture, a crucial step to prevent warping and improve the material's stability.

Craftsmanship excellence: from wood to TroWood Solid

After the initial storage period, the wood undergoes a controlled drying process in specialized chambers, followed by conditioning and further processing. This careful treatment is the basis for products intended for laser production.

The journey continues with the manual evaluation of each plank. Particularities such as cracks, defects, and knots are noted, and each piece is assigned its optimal use . Advanced sensors play an additional role in quality control, ensuring that only the finest wood is used. Our TroWood Solid range is sourced exclusively from wood that exceeds even the strictest criteria for the highest quality furniture.

The art of precision: artisanal homogeneity

The planks are transformed into slats and then carefully hand-sorted to achieve an incomparable natural appearance and the highest quality. After being skillfully glued, the slats undergo another phase of fine sanding and inspection.

Focused on minimizing waste and responsible resource management, the wood supplier operates on a strictly order-based system . This not only reduces waste but also contributes to sustainable resource use. As a champion of environmental awareness, it exclusively offers formaldehyde-free products in its range of materials.

From raw material to finished masterpiece

The premium solid wood panels are then sent to a local partner specializing in optimizing them for laser processing and ensuring a long service life. The panels undergo a final quality control check, precise cutting, and the application of a water-based lacquer . This lacquer has a dual function: preserving the wood's natural aesthetic and protecting it from external factors such as moisture. The result is wood that is even less prone to warping and optimally prepared for laser processing.

The journey from sourcing sustainable wood to crafting premium solid wood products is a testament to Trotec's dedication to quality, sustainability, and attention to detail . At every carefully executed step, they ensure the essence of each piece of wood is preserved, culminating in products that embody the beauty, strength, and sustainability of nature itself.